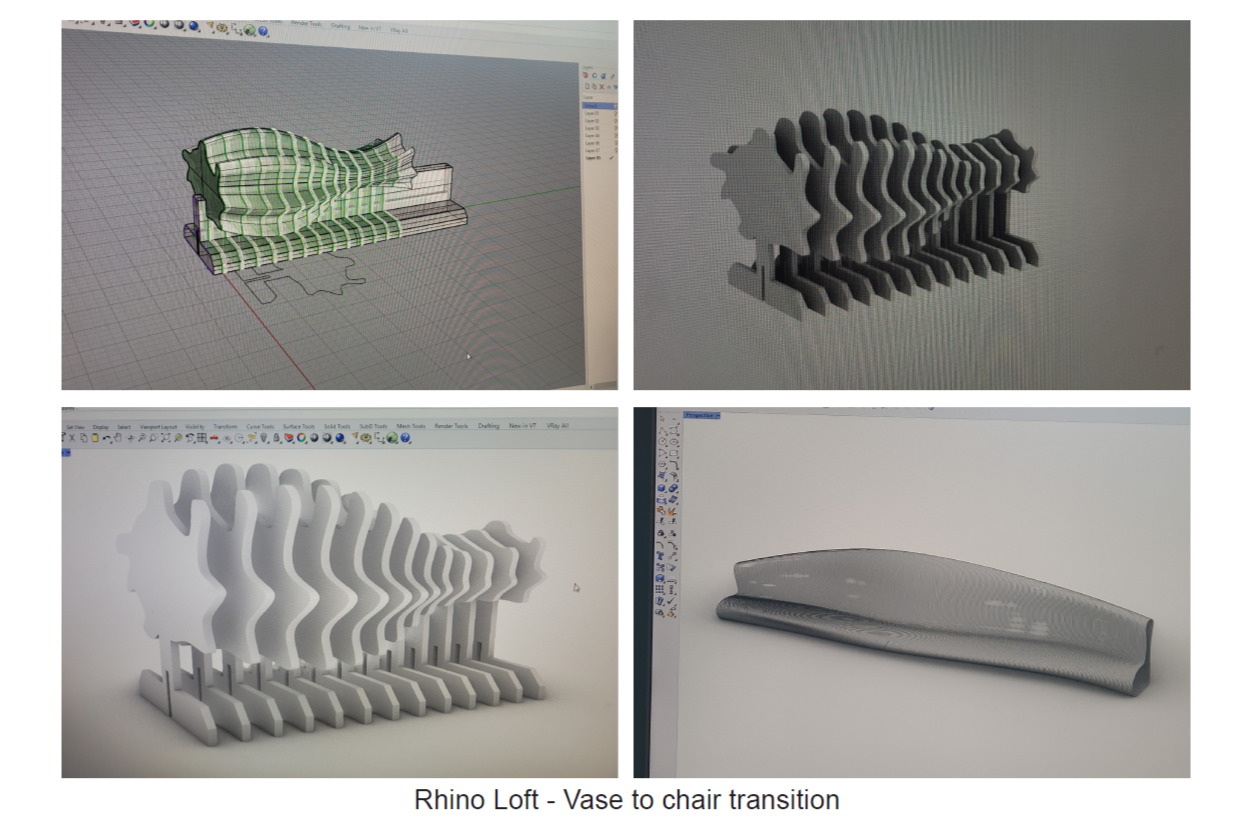

I worked on Lux Loft using Rhino7, creating curves and exploring structures specifically for a parametric chair design. Different iterations were achieved through adjusting curve points on the software. 1/8 inch plywood was used, and the pieces were directly laser cut onto the plywood. Lux Loft has 102 pieces including the jig.

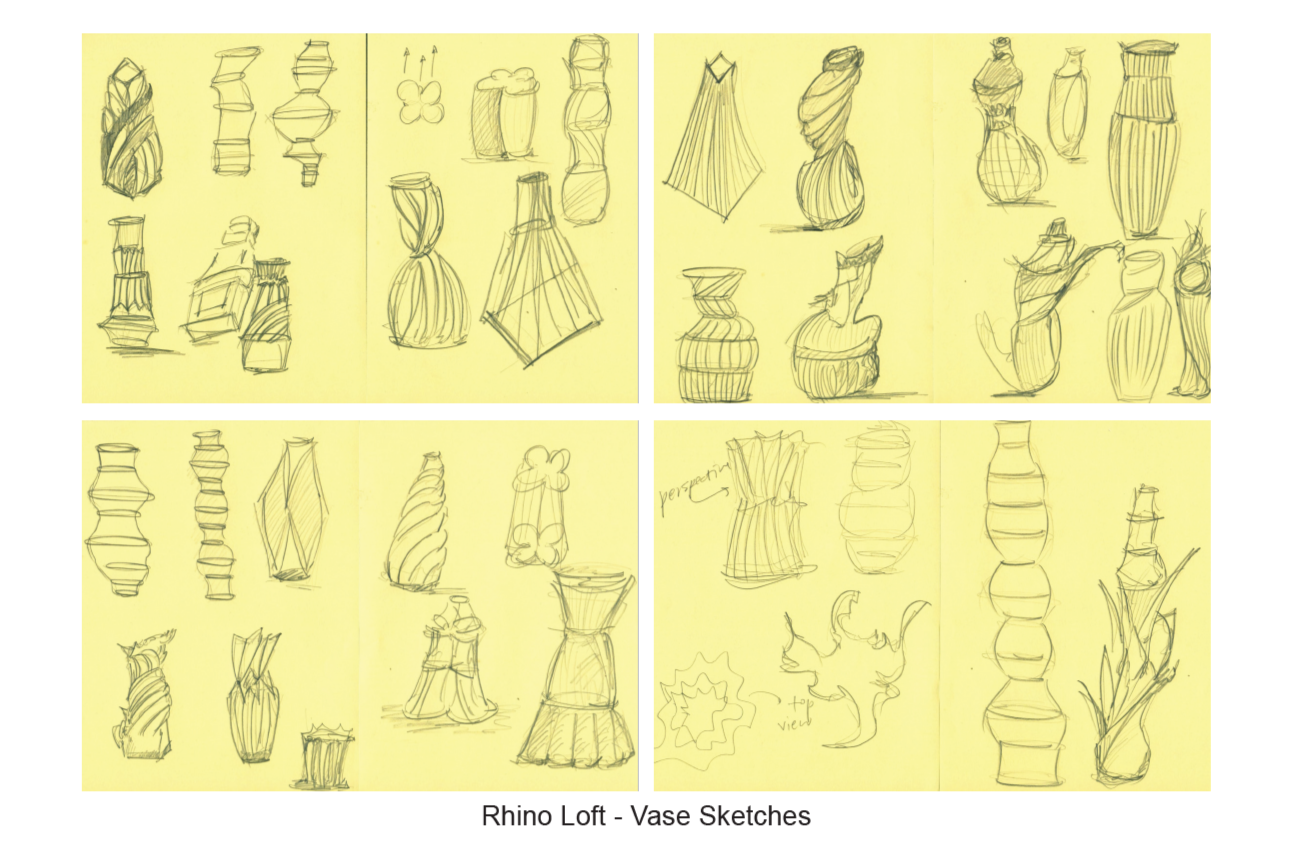

The first step was creating sketches on paper, then I moved on to Rhino7 to further solidify my vision. Once the curve points were adjusted and I was satisfied with the overall structure, I laid them out from the top view of the software. I later transferred them to Adobe Illustrator for the laser cutter to do its part, and finally, I was able to assemble the parts.

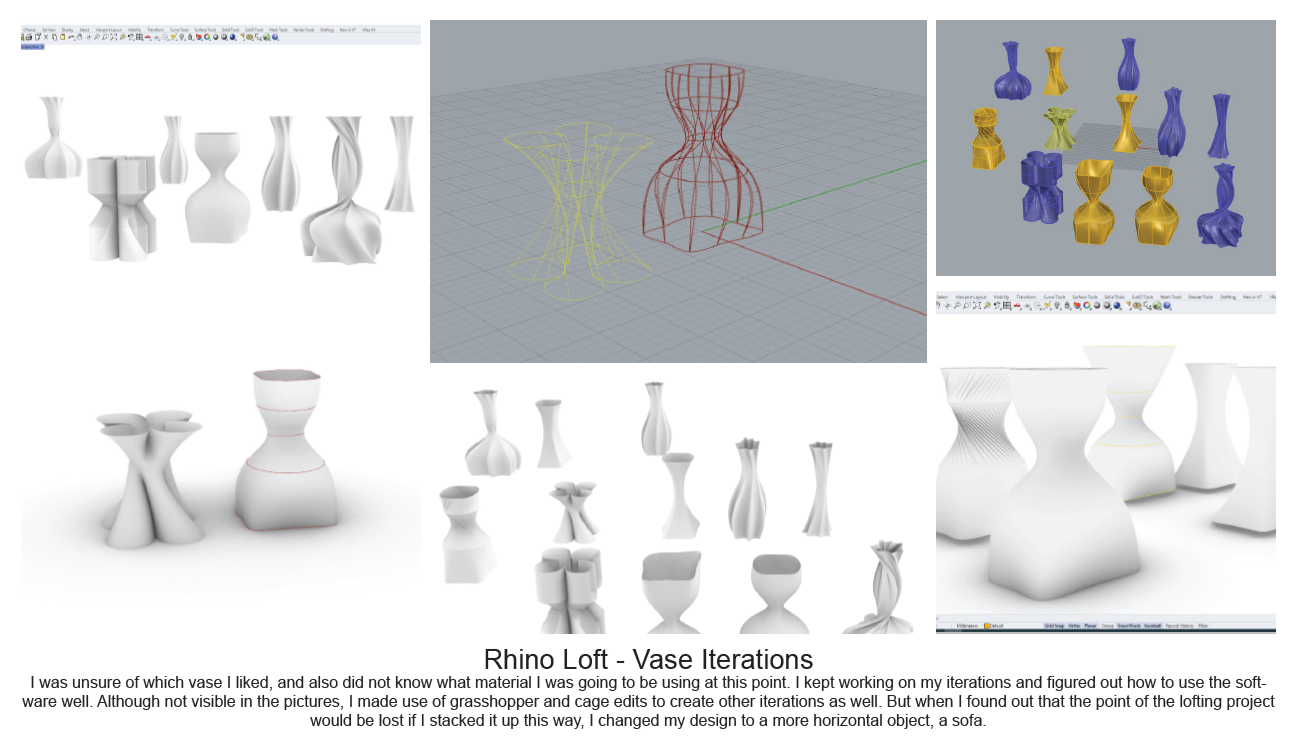

More about the process, and how this started as ideations to make a vase lofting project.